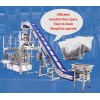

Eight Station Plastic Bag Sealers for Metal Nails

plastic bag sealers Manufacturer can suppy different filling machines,powder packaging solution,custom packaging solutions

Detail Information

Introduction of Eight Station Plastic Bag Sealers

I. Core Advantages and Features of Eight Sation Plastic Bag Sealers

1. High Efficiency and Reasonable Production Capacity

Typically, it can package 20-35 bags per minute (depending on the material and bag type), making it ideal for medium-sized production lines with a daily output of several to tens of tons.

Compared to a 6-station system, the additional stations can be used to add functions such as shaping, vacuum inspection, or additional feeding, reducing waiting time and streamlining the process.

2. High Functional Integration and Diverse Packaging Forms

The 8 stations typically complete the process sequentially: bag picking → bag opening → date printing (optional) → first feeding (e.g., main ingredient/powder) → second feeding (e.g., auxiliary ingredients/sauce) → vibration shaping/compression → vacuuming/nitrogen filling → heat sealing → finished product output.

It can achieve various complex packaging: such as vacuum packaging, nitrogen-filled preservation packaging, packaging with liquids, powder/granular packaging, block packaging, etc. The multiple stations allow for two or more feeding stations, suitable for products requiring combined packaging.

3. High Automation and Stability

The entire process, from bag picking to sealing, is fully automated, significantly reducing manual labor. Typically, one person can operate multiple machines, primarily for monitoring and replenishing materials.

The mechanical structure is relatively mature, and the control system (commonly PLC + touchscreen) is stable and reliable with a low failure rate, ensuring continuous production.

4. Precise Metering and Filling

It is compatible with various metering devices, such as multi-head combination scales (for granules/blocks), screw scales (for powders), liquid pumps, sauce filling machines, etc., providing high metering accuracy and reducing waste.

5. Wide Material and Product Adaptability

Wide Bag Type Adaptability: Handles various pre-made bag types, including three-side seal, four-side seal, stand-up pouches, zipper bags, and tote bags.

Wide Material Adaptability: Suitable for various pre-made bags made of composite materials, aluminum foil, PE, PET, etc.

Wide Industry Applications: Widely used in the food (snack foods, cooked foods, pickles, seasonings, frozen foods), daily chemicals, pharmaceuticals, chemicals, agricultural products, and many other industries.

6. User-friendly Operation and Maintenance

Touchscreen HMI (Human Machine Interface) allows for convenient and intuitive parameter settings (bag length, temperature, vacuum time, etc.).

Quick Product Specification Change: Different bag sizes can be switched by changing the bag maker and adjusting the program.

Modular design facilitates daily cleaning and maintenance.

II. Core Workflow (Typical Layout of 8 Stations)

Taking a common vacuum packaging machine as an example:

Station 1 (Bag Picking and Opening): The robotic arm picks up pre-made bags from the bag magazine and opens the bag opening using suction cups or grippers.

Station 2 (Bag Opening Inspection/Date Printing): Confirms the bag opening is correctly opened and allows for production date and batch number printing at this station.

Station 3 (First Filling): Typically, the main ingredient (such as solid granules) is fed in.

Station 4 (Second Filling): Additives, liquids, or sauces are added.

Station 5 (Vibration/Sorting): Vibration or pressing devices straighten the material inside the bag, preventing material from getting stuck at the seal and ensuring sealing quality.

Station 6 (Vacuuming/Inflating): The vacuum chamber is lowered to create a vacuum, or the process is switched to filling with a protective gas such as nitrogen.

Station 7 (Heat Sealing): The bag opening is heated and sealed.

Station 8 (Cooling and Output): After cooling, the finished bag is released onto the conveyor belt and sent out, completing the cycle.

Limitations of Eight Sation Plastic Bag Sealers

1.High requirements for pre-made bags: Pre-made bags must be used, and the quality of the bags themselves (such as neatness of the sealing edges, squareness of the pattern, and static electricity level) directly affects the bag loading rate and packaging effect.

2. Initial investment cost: Belonging to mid-to-high-end packaging equipment, the initial purchase cost is higher than manual or semi-automatic equipment, and also higher than integrated bag making and packaging machines.

3. Floor space requirement: Belonging to medium-sized equipment, requiring a certain amount of workshop space.

4. Changeover time: Although faster than complex equipment, changing to different bag sizes still requires replacing grippers, adjusting guide rails, etc., which requires a certain amount of time and technical expertise.

Please send your message to us

- Mobile Phone

- *Title

- *Content