Common packaging forms:

Three-dimensional self-standing bags (doypack, with zipper/optional zipper), pillow-style packages, three-sided sealed small bags, insert bags/large bags (for retail/bulk)

Core requirements:

Moisture-proof, oxygen-proof, and odor-proof migration prevention; usually nitrogen or air (N2) is used for nitrogenation to delay oxidation; the film material must be oil-resistant; high sealing strength to prevent oil leakage.

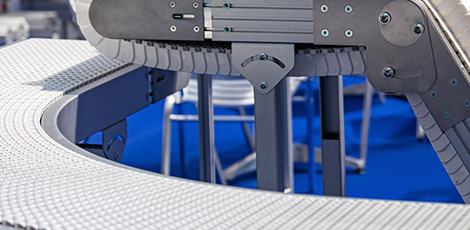

Recommended equipment combination:

Multi-head weighing machine (high measurement accuracy) + VFFS vertical bag-making filling sealing machine (for doypack or pillow-style packaging) + nitrogenation device (gas replacement) + nitrogen generator + date printer + metal detector/weight checker.

Packaging material suggestions:

Composite film (PET/PA/PE, PET/CPP, PA/PE), or single recyclable PE-based film (if pursuing recyclability), inner layer with oil-resistant coating or release layer.

Contact Experts for Nuts Solutions