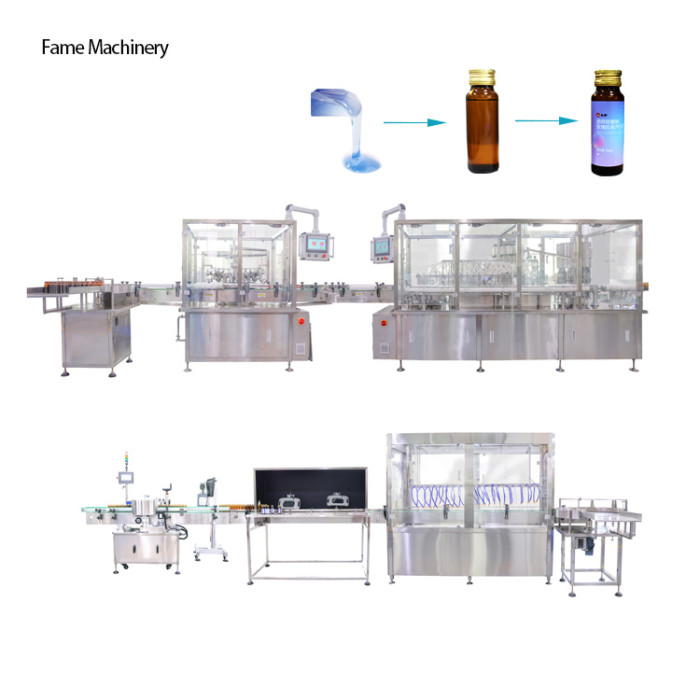

Oral Liquid Packaging Solutions for Complete Packaging Line

Oral Liquid Packaging Solutions for complete packaging line supplier,we can customize different packaging solutions for different products

| Share | |

|---|---|

| Categories | Complete Packaging Line |

| Trademark/Brand | fame machinery packaging machines manufacturer |

| Model | FM007 |

| Packaging products | Liquid |

| Filling specification | 30-1000ML |

| Hopper size | 150L(304 stainless steel ) |

| Machine power | 9Kw |

| FOB port | Guangzhou/Shenzhen |

| Terms of Payment | Western Union, MoneyGram, T/T, Paypal |

| Update Time | Jan 22,2026 |

Detail Information

Introduction of Oral Liquid Packaging Solutions for complete packaging line

Oral liquid packaging solutions for complete production lines offer numerous significant advantages, meeting the high demands of modern manufacturing for flexibility, efficiency, cost control, and market responsiveness. Below is a detailed analysis of their main advantages:

1. High Degree of Automation

Fully Automatic Operation: From bag feeding, opening, filling, sealing to output, everything is completed automatically, reducing manual intervention and labor intensity.

Intelligent Control: Utilizes a PLC (Programmable Logic Controller) or industrial computer to achieve parameter setting, fault diagnosis, production statistics, and other functions, making operation simple.

2. High Production Efficiency

High-Speed Operation: Speed can be adjusted according to bag size and material characteristics; a typical production line can package dozens to hundreds of bags per minute.

Continuous Operation: Supports 24-hour uninterrupted production, suitable for large-volume orders.

3. Good Flexibility

Multi-Specification Adaptability: By changing molds or adjusting parameters, it can adapt to packaging bags of different sizes and materials (such as stand-up pouches, zipper bags, back-seal bags, etc.).

Multi-functional Integration: Can be equipped with modules such as weighing machines, coding machines, vacuum nitrogen filling, and date printing to meet diverse needs.

4. High Precision

Precise Measurement: Employs weight, volume, or counting measurement methods with minimal error (e.g., food packaging accuracy can reach ±0.5g~1g).

Stable Sealing Quality: Controllable heat sealing temperature and pressure ensure smooth and secure sealing, preventing air leakage or bag breakage.

5. Strong Hygiene and Safety

Materials Compliant: Components in contact with materials are typically made of stainless steel or food-grade plastic, meeting GMP, HACCP, and other hygiene standards.

Safety Design: Equipped with safety doors, emergency stop buttons, and protective covers to ensure operator safety.

6. Energy Saving and Environmental Protection

Reduced Waste: Precise measurement reduces material loss, and optimized sealing processes minimize packaging material waste.

Low Energy Consumption Design: Energy-saving technologies are frequently used in motors and heating systems, reducing operating costs.

7. Stability and Durability

Robust Structure: Key components utilize high-strength materials, are wear-resistant and corrosion-resistant, suitable for long-term high-load operation.

Easy Maintenance: Modular design facilitates cleaning and maintenance, reducing downtime.

8. Wide Adaptability

Diverse Materials: Handles granules, powders, liquids, pastes, and lumps (such as snacks, milk powder, detergents, seeds, etc.).

Industry Compatibility: From food processing to chemical products, simply adjust the equipment configuration to suit different industry needs.

Please send your message to us

- Mobile Phone

- *Title

- *Content