Home / All / Complete Packaging Line / Custom Packaging Solutions for complete packaging line Food Packaging Solutions Supplier

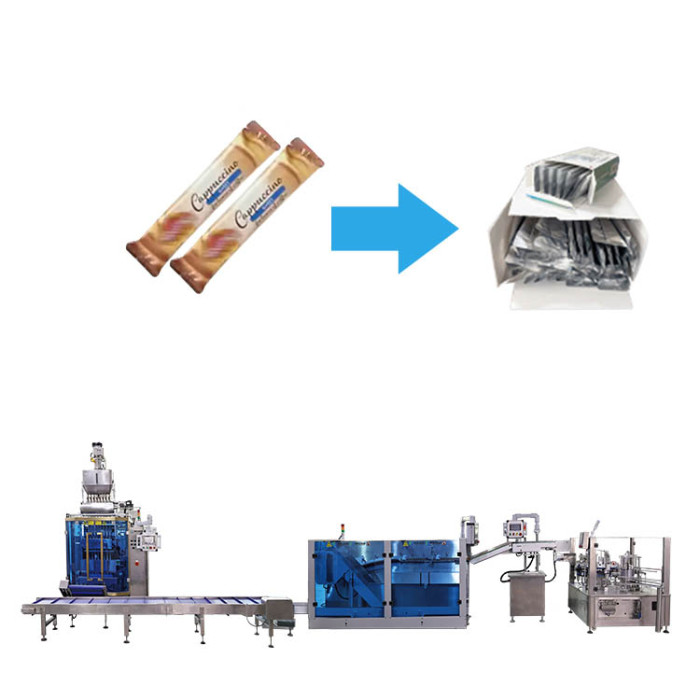

Custom Packaging Solutions for complete packaging line Food Packaging Solutions Supplier

Custom Packaging Solutions manufacturer can suppy different sealing machines and filling machines,paste packaging solution

| Share | |

|---|---|

| Categories | Complete Packaging Line |

| Trademark/Brand | fame machinery packaging machines manufacturer |

| Model | FM007 |

| Packaging products | Liquid and pastes granule |

| Filling specification | 30-1000ML |

| Hopper size | 150L(304 stainless steel ) |

| Machine power | 9Kw |

| FOB port | Guangzhou/Shenzhen |

| Terms of Payment | Western Union, MoneyGram, T/T, Paypal |

| Update Time | Jan 22,2026 |

Detail Information

Introduction of Custom Packaging Solutions For Complete Packaging Line

Custom packaging solutions for complete production lines offer numerous significant advantages, meeting the high demands of modern manufacturing for flexibility, efficiency, cost control, and market responsiveness. Below is a detailed analysis of their main advantages:

1. High Flexibility and Customization Capabilities

• Adaptability to Diverse Products: Production line parameters can be quickly adjusted according to different product sizes, shapes, and materials (e.g., food, cosmetics, industrial parts), supporting small-batch, multi-variety production.

• Personalized Design: Meets brand owners' customization needs for packaging appearance and function (e.g., stand-up pouches, zipper bags, vacuum packaging), enhancing product uniqueness.

2. Increased Production Efficiency and Automation

• High-Speed Continuous Production: Automated equipment can achieve packaging speeds of tens to hundreds of bags per minute, far exceeding manual operation.

• Reduced Human Intervention: Automated feeding, filling, sealing, and inspection processes reduce labor costs and improve consistency.

• 24-Hour Continuous Operation: Suitable for large-scale orders, shortening delivery cycles.

3. Optimized Cost Control

• Reduced Material Waste: Precisely controls the amount of packaging materials used (e.g., film, labels), avoiding over-packaging. • Reduced Long-Term Costs: Although initial investment is higher, automated production lines achieve long-term returns by reducing manpower and increasing yield.

• Energy-Saving Design: Modern customized production lines often integrate energy optimization systems (such as high-efficiency heat sealing and low-power motors).

4. Guaranteed Product Quality and Consistency

• High-Precision Control: Precisely controls parameters such as filling volume, sealing temperature, and pressure, reducing errors.

• Integrated Inspection System: Equipped with visual inspection, metal detection, and weight verification functions, it rejects defective products in real time.

• Compliance with Industry Standards: Easily meets hygiene and safety certifications (such as ISO, HACCP, GMP) for the food and pharmaceutical industries.

5. Enhanced Market Response Capabilities

• Rapid Product Line Switching: Modular design supports rapid mold changes or process adjustments to adapt to market changes.

• Shorter Time to Market: Customized production lines can quickly develop adaptation solutions for new products, accelerating product iteration.

6. Technical Support and Intelligent Upgrades

• Data Monitoring and Analysis: Real-time collection of production data through PLC and Internet of Things (IoT) systems optimizes processes and predicts maintenance needs.

• Remote Maintenance and Diagnostics: Suppliers can provide remote technical support, reducing downtime.

• Future Expansion Compatibility: Flexible design facilitates the integration of new technologies (such as AI quality inspection and robotic palletizing).

7. Environmental Protection and Sustainable Development

• Material Adaptability: Compatible with biodegradable and recyclable materials (such as PLA and paper-based composites), supporting environmental initiatives.

• Reduced Carbon Footprint: Efficient production reduces unit energy consumption, aligning with green manufacturing trends.

Please send your message to us

- Mobile Phone

- *Title

- *Content